LDPE Properties:

1. Flexibility and Durability: LDPE offers more flexibility than other types of polyethylene. This flexibility allows it to be used in a wide range of applications without breaking or cracking. In addition, its low-density structure makes the material lightweight and easy to process.

2. Chemical Resistance: LDPE is resistant to various chemicals and solvents. This feature makes it ideal for packaging and storing products containing chemicals.

3. Low Melting Point: LDPE's melting point is around 105-115°C. This makes it suitable for products that need to be shaped at low temperatures. However, its use in hot environments is limited because it can melt at high temperatures.

4. Transparency and Surface Structure: LDPE can be naturally translucent or transparent. This feature makes it preferred in applications such as food packaging and transparent bags. In addition, its surface is smooth and generally gives a slippery feeling.

5. Low Water Absorption: LDPE is a material with a very low water absorption rate. Thanks to this feature, it is widely used in applications requiring waterproofing.

Areas of Use of LDPE

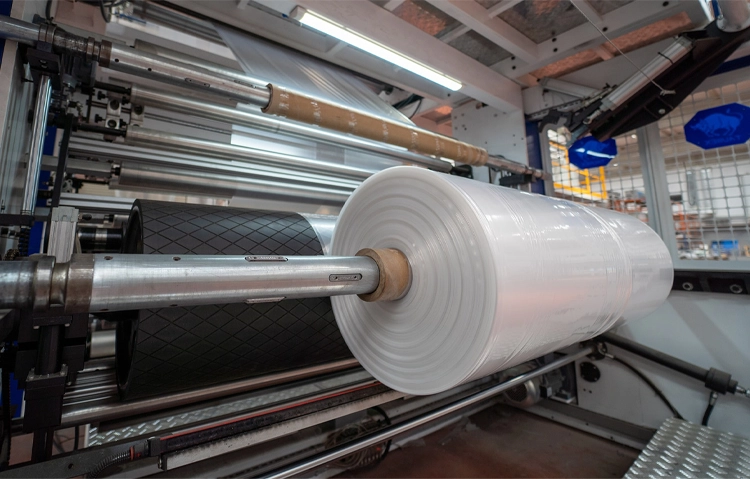

1. Packaging Industry: LDPE is widely used in products such as flexible packaging materials, plastic bags, food wraps, film coatings and garbage bags. Its light and flexible structure makes it preferred in the production of these products.

2. Bottles and Containers: LDPE is also used in the production of products such as flexible bottles, containers, tubes and canisters. Its transparency and chemical resistance allow these products to be used safely in the storage of food, cosmetics and chemicals.

3. Electrical Insulation: LDPE is a good electrical insulator. For this reason, it is preferred in applications such as cable coverings and electrical insulation materials.

4. Agriculture and Construction: LDPE is used in the agricultural sector in areas such as covering greenhouses, irrigation pipes and packaging of various agricultural products. In the construction sector, it is preferred in underground membranes, waterproofing layers and concrete molds.

5. Toys and Home Products: LDPE is used in the production of a variety of daily use items such as children's toys, shower curtains, water bottles and other household products. Its flexibility and chemical resistance ensure that these products are safe and long-lasting.

LDPE Advantages and Disadvantages

Advantages:

- Flexibility and Lightness: LDPE's flexible structure provides convenience in many applications. Its light weight makes it easy to handle and process.

- Chemical and Moisture Resistance: LDPE has high resistance to many chemicals and moisture, making it ideal for a variety of packaging and insulation applications.

- Cost Effectiveness: LDPE is generally considered a cost-effective material because it can be produced on a large scale and is easy to process.

Disadvantages:

- Low Temperature Resistance: LDPE is not resistant to high temperatures. Its low melting point limits its use in applications requiring high temperatures.

- Low Mechanical Strength: LDPE has less strength than other types of polyethylene. This can be a disadvantage in applications requiring high durability.

- Recycling Challenges: LDPE can be recycled, but the process is more complex than other polymers and may require special equipment.

Low Density Polyethylene (LDPE) is a widely used material in many sectors with its flexibility, chemical resistance and low cost. LDPE, which is especially indispensable in the packaging industry, is also preferred in various applications in construction, agriculture, electricity and daily life. Despite its disadvantages such as limited resistance to high temperatures and recycling difficulties, the advantages offered by LDPE have made it one of the indispensable polymers of the industry. With developing technology and production methods, the areas of use of LDPE are expected to expand even further.